Ways Precision CNC Machining Can Help Businesses

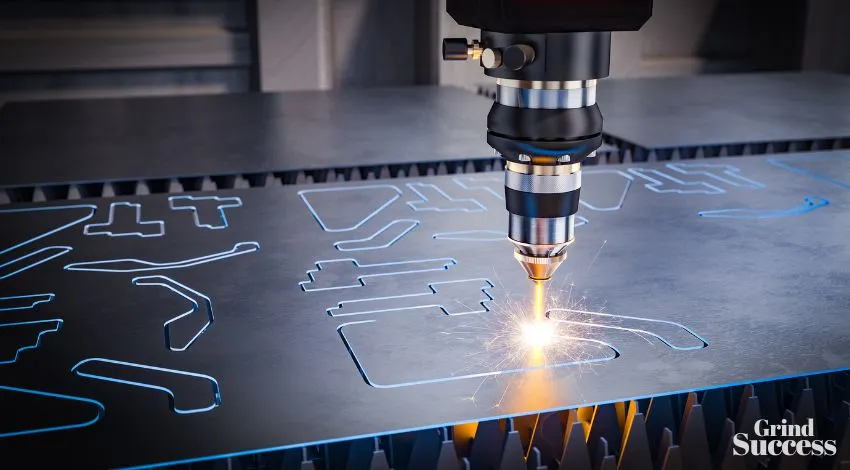

CNC machining is a process that incorporates computer-controlled machines to create high-precision parts from various types of materials.

This technology has revolutionized the manufacturing industry and made it possible to create complex parts with high accuracy. CNC machining is used in different aerospace, automotive, and medical industries.

CNC machining services are a vital part of any business that relies on manufacturing or producing products. CNC precision machining allows businesses to create parts and products with high accuracy and precision.

This is especially imperative for companies that produce products requiring tight tolerances or meeting specifications.

In addition, CNC machining can help businesses save time and money by reducing the amount of scrap material and waste.

Benefits Of Precision CNC Machining

Versatile

The first benefit is that the process is very versatile. It can be used on various materials, including metals, plastics, and composites.

This means that the machine can cut from a wide range of materials, which gives designers and engineers more options when choosing the suitable material for their application.

Reduced cycle time

Precision CNC machining can offer reduced cycle time. By using these machines, manufacturers can produce parts with tight tolerances quickly and efficiently.

In addition, CNC machining can help to improve the quality of the finished product. Manufacturers can stay competitive in today’s market by using the latest technology.

Lower labor costs

By investing in CNC machines, manufacturers can automate tasks that would otherwise have to be completed by hand. This saves on labor costs and also increases efficiency and productivity.

These machines are also much more precise than human workers, producing better-quality products. In addition, it can work faster than humans, meaning that manufacturers can increase output without sacrificing quality.

Better Tool Performance

When it comes to machining, cutting tools are everything. The operation will suffer if they are not up to par.

With CNC precision machining, the cutting tools are of the highest quality and perform higher than traditional machining methods. This results in better overall tooling performance, increasing productivity and efficiency.

Reliability

In any manufacturing setting, reliability is critical. Downtime is expensive and can lead to lost business. With precision CNC machining, there is greater reliability thanks to the achievable tight tolerances.

High-quality parts

Precision CNC machining allows the creation of high-quality parts with high accuracy. It is typically used for applications where a high level of precision is required. Such as in the aerospace or medical industries.

Precision CNC machining can also create parts with complex geometries or shapes that would be difficult to produce using traditional methods.

Less Wastage

With traditional machining methods, it is not uncommon for up to 30% of the material to be wasted. This is because the machinist has to allow for a certain amount of material to be removed to achieve the desired result.

Precision CNC machining eliminates this waste by allowing the machine to cut away only the necessary amount of material.

Much Faster

Another benefit of CNC machining is that it is much faster than traditional methods. This is because the machine can work for long periods without rest, meaning that parts can be produced much faster.

In addition, precision CNC machines can produce parts with much higher accuracy than traditional methods. This means there is a lesser chance of error and that parts will fit together better.

Investing in precision CNC machining can help manufacturers save money and increase efficiency. In today’s competitive marketplace, these are essential ingredients for success.

Conclusion

The benefits of precision CNC machining are clear. This technology gives manufacturers more control over production, producing more consistent and accurate products.

Additionally, it can save time and money by reducing the need for rework and scrap. With these pros, it is no wonder that CNC machining is becoming increasingly popular in a variety of industries.

This is a Contributor Post. Opinions expressed here are opinions of the Contributor. Grindsuccess does not endorse or review brands mentioned; does not and cannot investigate relationships with brands, products, images used and people mentioned, and is up to the Contributor to disclose.